1500bbl/day Brewery Plant

- Apr 12, 2025

- 199

- tiantai

1) Brief Introduction

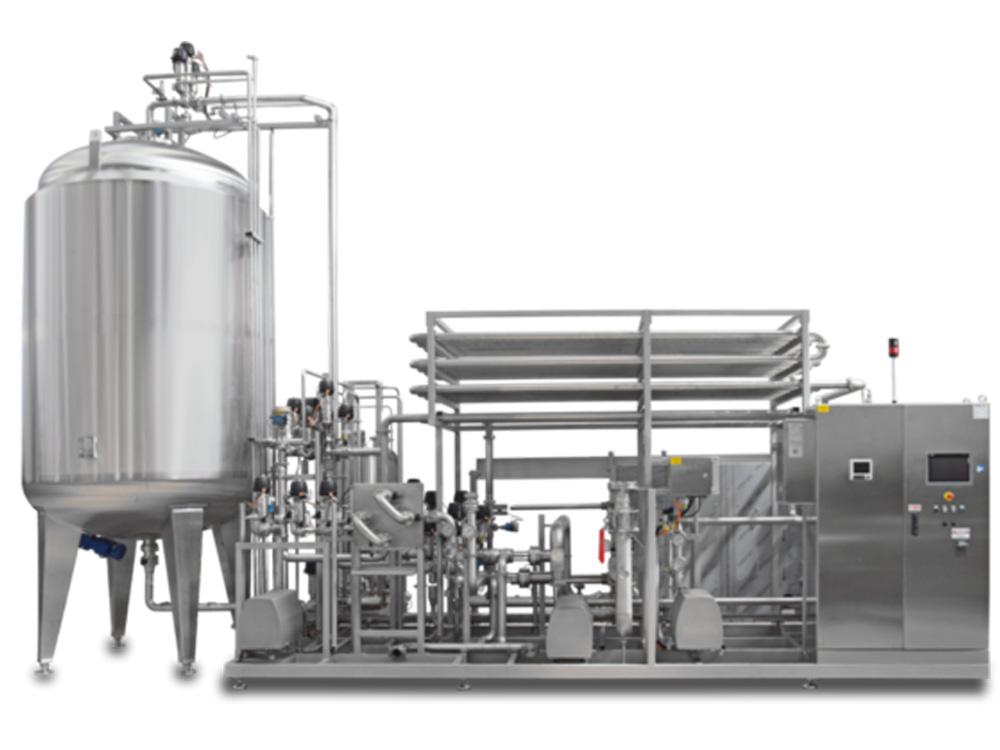

Tiantai offers a wide choice of industrial brewery plant and technology to customers at an optimal cost. Brewery equipment configuration is designed keeping in mind the raw materials, capacity and brewing profile of different brands. The process automation and control philosophy is developed to match volumes, efficiency and consistency of the final product. Our brewery plant comply with the latest and stringent international standards. In this article, we will introduce configuration of 1500bbl/day brewery plant.

.jpg)

2) General Configuration of 1500bbl/day Brewery Plant

| Malt Handling System | Malt Feed Hopper |

| Malt Elevator | |

| Malt Classifier | |

| De-stoner | |

| Plate Type Magnet | |

| Mill Feed Hopper | |

| Malt Mill | |

| Grist Case | |

| Grist Conveyor | |

| Dust Collection System | |

| Brewhouse and brewing water section | 120bbl Cereal Cooker |

| 200bbl Mash Tun | |

| 200bbl Lauter Tun | |

| 200bbl Kettle Tun | |

| 200bbl Temporary Storage Tun | |

| 200bbl Whirlpool Tun | |

| 600bbl Hot Water Tun | |

| Valves, Pumps, Heat Exchanger, Various Sensors | |

| Yeast propogation, storage and pitching | Carlsberg Flask |

| Yeast Propagator -1 | |

| Yeast Propagator -2 | |

| Yeast Storage Tanks | |

| Yeast Pitching and Cropping Pump | |

| Process&Utility Piping | |

| Field Instrument | |

| Fermentation and maturation section | 6 x 600bbl Fermentation Unitank |

| 10 x 800bbl Fermentation Unitank | |

| 16 x 1200bbl Fermentation Unitank | |

| Filtration section | DE Filter |

| Bright beer section | 2 x 800bbl Bright Beer Tank |

| 2 x 1200bbl Bright Beer Tank | |

| CIP system for brewery | 3KL Caustic Tank |

| 3KL Hot Water Tank | |

| 3KL Acid Tank | |

| 3KL Sterile Tank | |

| Pumps, Valves, and Various Sensors | |

| Field instruments, control system, and automation | Full Automation |

| Electrical for brewery | Cables, Signal Wire |

| All other necessary auxiliary equipment | Cable Bridges, Support, and others |

3) Technical Basis of 1500bbl/day Brewery Plant

| Brew Length ( Cast Cold Out) | 200bbl |

| Brew Batches per day | 1-6 batches |

| No. of working days | 300 |

| Cold wort collection per day | 600bbl/800bbl/1200bbl |

| Design based on brew plato | 15 |

| Maximum Output Plato | 19 |

| Minimum Output Plato | 12 |

| Malt spent grain thickness | 25cm - 38cm |

| Evaporation Rate: | 8% - 10% |

| Voltage Supply | 400V, 3 Phases,50HZ AC, 24V DC or customized |

| Water Supply Pressure | 2 - 6 bar |

| Steam Working Pressure | 2 bar |

| Air Source Pressure | 2 - 8 bar |

| Brewery Expanding | Available |

4) Automation Level of 1500bbl/day Brewery Plant

To realize maximum automation level

* Valves automation: pneumatic butterfly, pneumatic angle seat valve, pneumatic ratio angle seat valve

* One click brewing to save manual operation and reducing error rates

* Auto water mixing station for mashing or sparging

* Auto wort cooling station to reach needed fermentation temperature

* Auto brewing process, includes mashing, lautering, boiling and whirlpool

* Auto discharge of spent grain

* Auto mashing in before official brew day to save time and help streamline your mashing process

* Auto vessel pre-heating to save time and improve brewing consistency.

* Auto vessel flushing to maintain high level cleanliness and efficiency in brewing

* Recipe storage for different types beer

* Auto alarm protection

* Auto security protection

* Auto log archiving

Tiantai provides turnkey solutions on brewery equipment, if you have the plan to build an industrial brewery plant, I am at your disposal anytime.